Manufacturing Infrastructure

We consistently enhance our processes, prioritizing innovation to achieve cost-efficiency while maintaining quality and technical specifications. Our multipurpose assets, with a capacity of more than 27,000 MT across six highly automated manufacturing sites equipped with glass-lined, titanium-clad, silicon carbide, ETFE-coated, Hastelloy, and stainless-steel reactors, enable us to produce a diverse range of products.

Supported by a Distributed Control System (DCS) with Hard Wire Systems, SCADA, and PLC, these technologies help us scale production efficiently and consistently deliver products that meet customer expectations, enhancing our operational flexibility to quickly adapt to evolving market demands.

Manufacturing technology

Continuous process technology

We employ continuous process technology for various chemical reactions, utilizing techniques such as flow reactors (flow chemistry) and photo reactors (photochemistry). Given its numerous benefits, we aim to transition our commercial processes and products to these technologies.

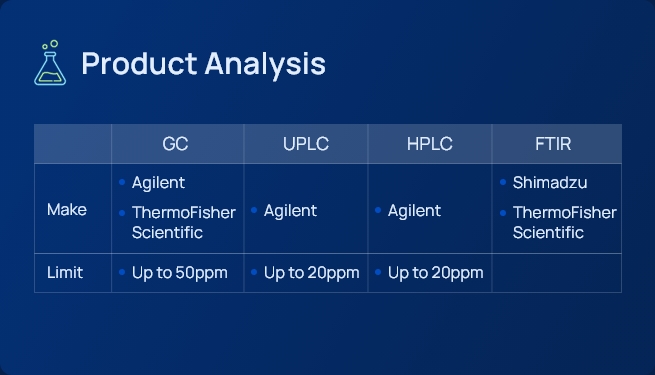

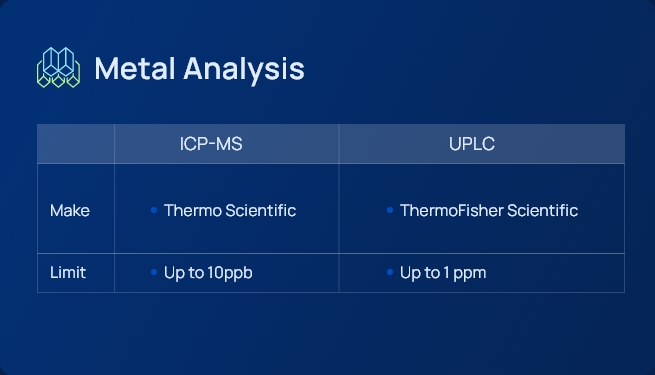

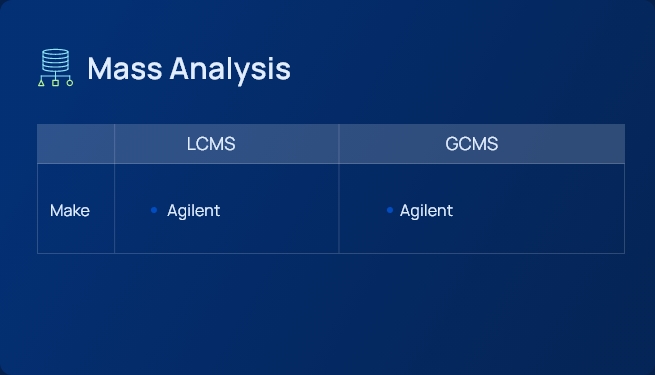

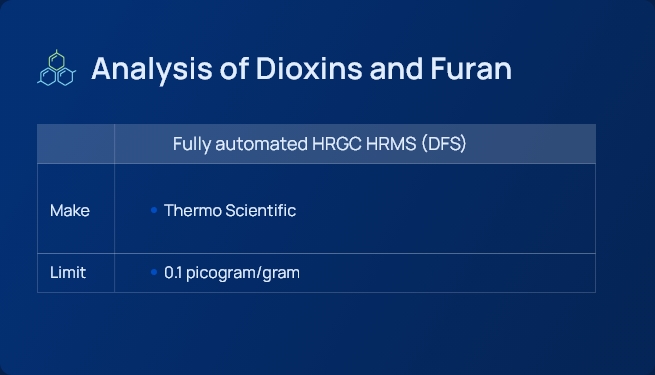

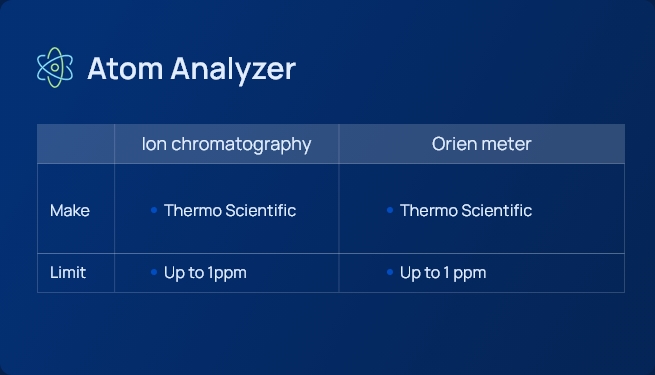

Analytical capabilities

Waste treatment technology

We have the following waste treatment systems - ETP, SBT, MEE, Bioreactors and ZLD.

Effluent treatment plants play a vital role in reducing the environmental impact of industrial activities and are key to achieving zero-liquid discharge (ZLD). By incorporating Effluent Treatment Plants (ETP), Multiple Effect Evaporators (MEE), Soil Biotechnology (SBT), and Reverse Osmosis, we are enhancing our ability to treat higher volumes of effluent and recover water.

This integrated approach supports sustainable practices and ensures compliance with environmental regulations.

Our certifications