Excellence at every stage,

from conceptualization to commercialization

Our in-house research and development facility is equipped with state-of-the-art laboratories and is recognized by the Department of Scientific and Industrial Research (DSIR). Engaged in process innovation, development and new chemical entity screening, it seamlessly optimizes the entire system from product conceptualization to commercialization.

Central to our research and development efforts are the following key factors:

- Addressing changing consumer trends

- Industry development

- Developing innovative processes

- Undertaking complex chemistries

- Environmental management

- Developing operating efficiencies

Delivering quality of

the highest standard

Developing high-quality molecules is essential for the growth and success of our organization. Developing safer processes by utilizing our meticulously designed systems with advanced process control at every stage of the product lifecycle, and our commitment to quality spans from initial research to commercial development. Our dedicated team of qualified professionals strives to ensure this and continuously enhance the entire value chain.

90+

Scientists

90+

Molecules in R&D and Pilot

80+

Fume Hoods

3

R&D Centers

Our research and development capabilities

Batch reactors

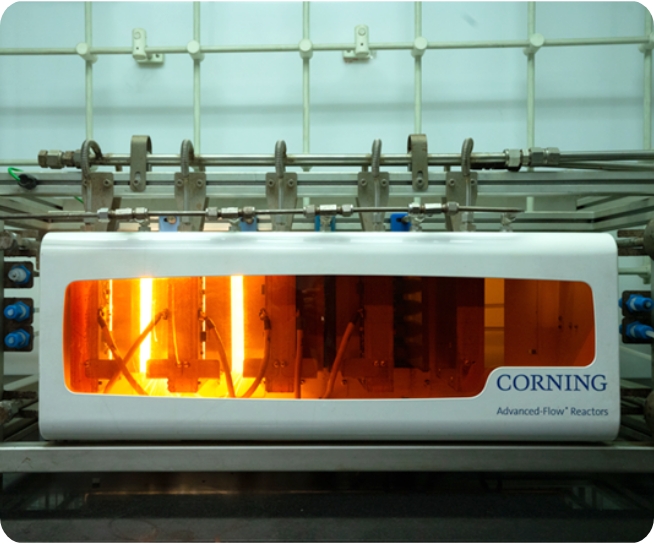

Continuous and flow reactors

Pressure reactors

Loop reactors with different light sources

Harnessing continuous process technology

We are one of the very few organizations that efficiently utilize continuous process technology for various chemical reactions. It offers several distinct advantages over traditional batch processes, such as:

- Minimizes batch cycle time

- Energy and cost-effective

- Maximum quality control

- Safer and eco-friendly process

- Higher level automation

- Optimal inventory storage

Photochemistry is being increasingly used in developing novel synthesis routes for compounds in specialty chemicals and pharmaceuticals. By utilizing ultraviolet and visible light to energize molecules, it facilitates the formation of new chemical bonds. We use this technology in developing products for our customers, acknowledging its potential to revolutionize our focus area.

This technology enables continuous and accurate raw material input and product extraction. It facilitates multi-ton reactions in compact plants, utilizing low chemical concentrations for cost-efficiency. We are among the few leading Indian companies to implement continuous flow chemistry technology on a commercial scale.

Creating safe and

compliant processes

Process safety is of utmost importance to us and is further enhanced through Differential Scanning Calorimeter (DSC) and Reaction Calorimeter (RC). We also undertake proactive measures to identify problems and mitigate hazards through process improvement, engineering controls, safe operating procedures and continuous employee training. Our strict adherence to regulatory compliance ensures we meet the highest safety standards at every stage of the process.